ABOUT LIGNOFUN

Lignin to high-value applications

LIGNOFUN plans to establish bio-based aromatics as an integral part of international markets, thereby creating sustainable alternatives to fossil-based raw materials. This market acceptance will be demonstrated through a series of relevant product applications, with stakeholders actively involved in the validation process.

Renewable Feedstocks

The pulp and paper industry in Europe produces 17 million tonnes of lignin every year. However, only two per cent is used for purposes other than energy production. LIGNOFUN set its goal on revalorizing the lignin from the paper & pulp industry for the production of bio-aromatic compounds.

Lignin utilization starts off from the two abundant side streams black liquor and kraft lignin. Originating from certified wood feedstock and being regionally sourced and processed, the Black Liquor used for this value chain holds great potential as a renewable raw material that stands in no conflict with food and feed production. The developed processes will be aligned with the existing value chains allowing them to fit seamlessly into sourcing and processing standards.

Bio-based aromatics production through innovative depolymerization processes

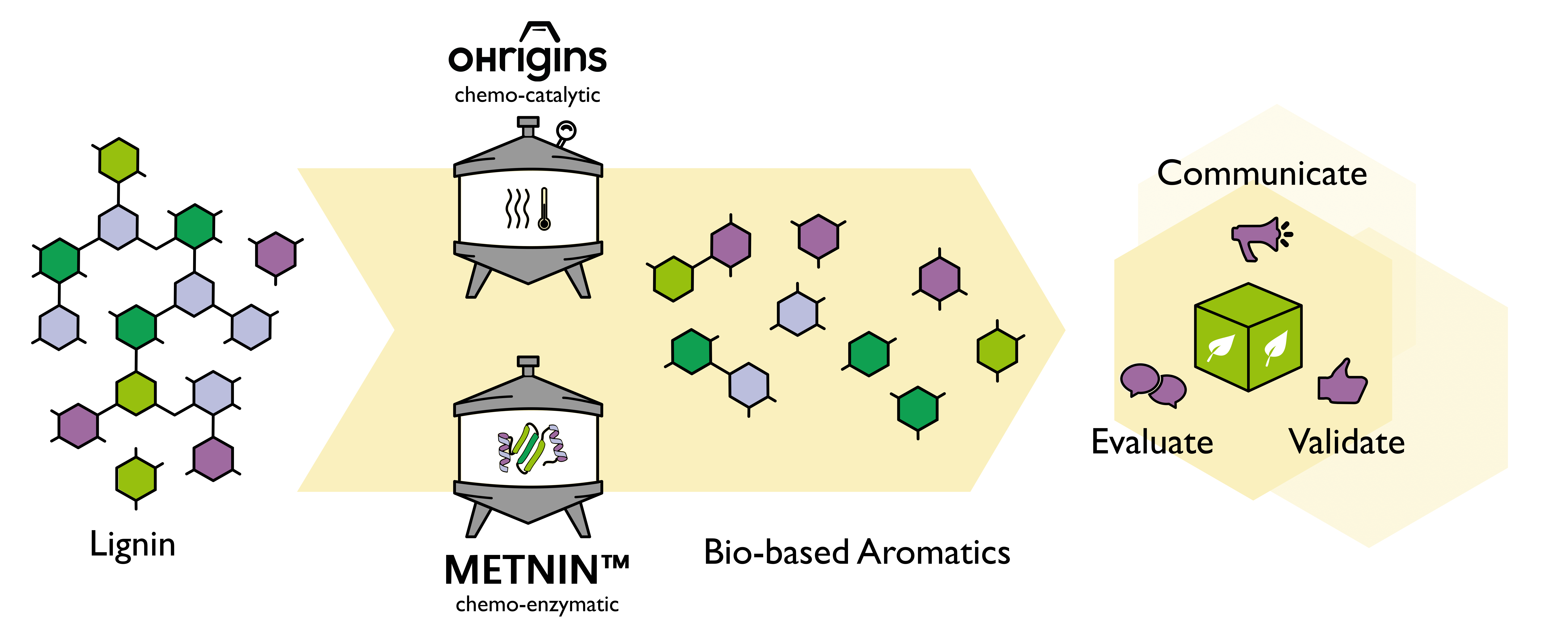

Starting from Black Liquor, LIGNOFUN produces Kraft Lignin as a starting point for further depolymerization and refinement. The foundation for subsequent technology development and product validation is based on two revolutionary depolymerization technologies – METNIN™ and OHRIGINS™ – both offering high reaction control and yielding tailor made compounds in the process.

METNIN™ a chemo-enzymatic process based on laccase-catalyzed reactions that has already been proven economically feasible and ready to hit industrial scale. The process yields fractions differing in molecular weight and oligomerization offering various applications like bio-based resins, adhesives, insulation composites or rigid foams.

OHRIGINS™ technology utilizes a chemo-catalytic depolymerization process to produce bio-based phenolics. The process offers high control over process parameters to minimize repolymerization or crosslinking effects, yielding targeted compounds for antioxidant, resin and adhesive applications. Due to its iterative nature, all reagents are recovered during DSP leaving behind an aqueous effluent stream that is ready to be reintroduced into pulp and paper mill processes.

Technology and Prototype validation

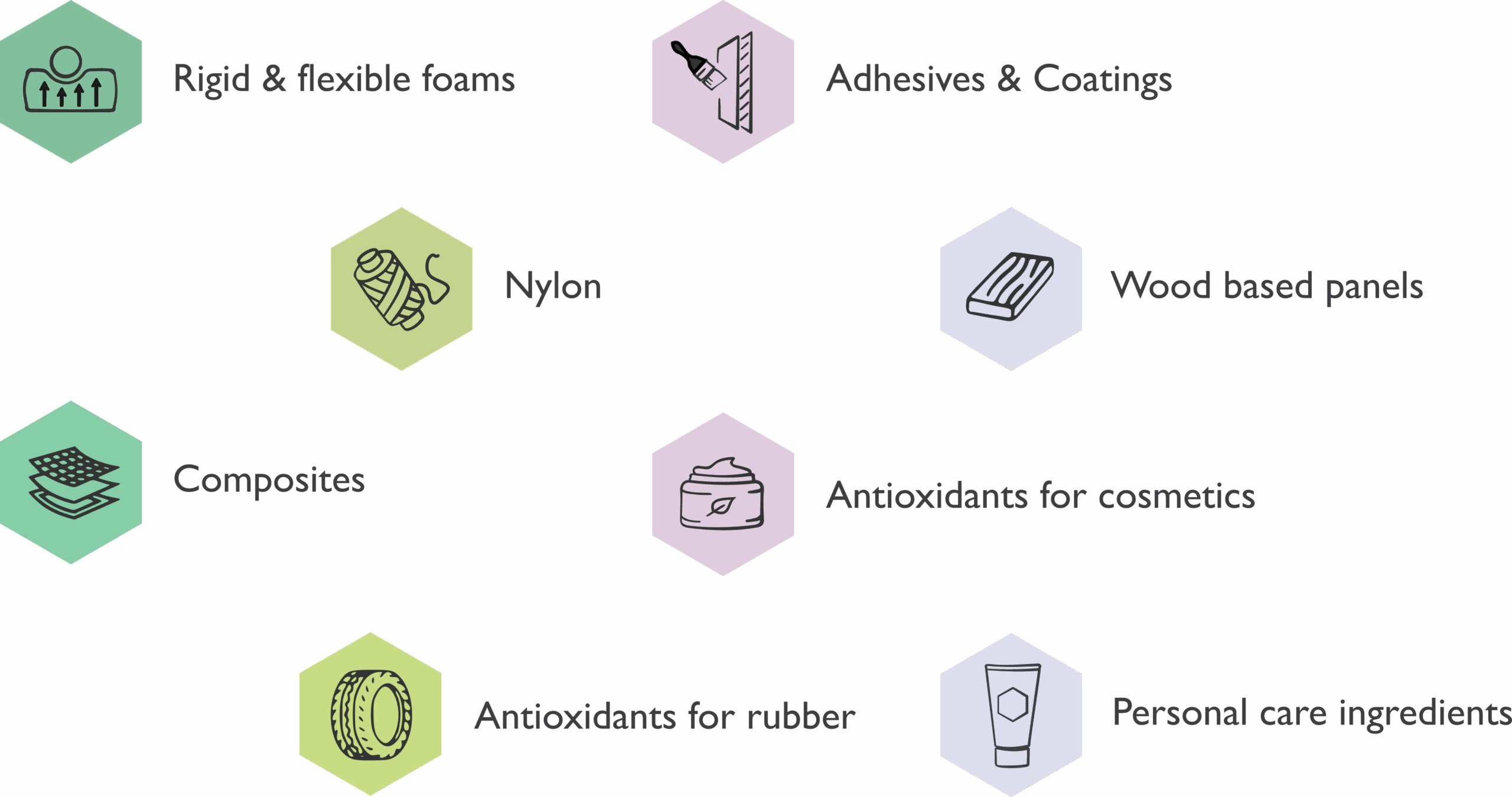

Securing a sustainable stream of bio-based aromatics is only the first part of LIGNOFUN. In the following work block, the refinement of the lignin-derived aromatic streams into intermediate products (phenolic, resins, PUR, antioxidants) becomes the focus of the operation. Through various processes demonstration prototypes (like, nylon 66, adhesives, coatings, composites, wood panels, cosmetics, personal care products and rubber products) are developed and subsequently tested and validated. Demonstrating the economic viability and superior performance of these products will facilitate industry adoption, fostering collaboration among stakeholders and deliver bio-based alternatives for strategic industrial sectors in the EU.

Product applications

LIGNOFUN aims to create high impact across multiple lignin-based value chains, contributing to European economic, environmental, societal, and strategic needs.

Impact assessment and stakeholder engagement

LIGNOFUN aims to create impact along the whole value chain. The development and optimization of our depolymerization processes, scale-up activities, strain development, refinement strategies, and product development are therefore considered in the context of market readiness and economic and environmental and social sustainability. To this end the project will perform techno economic analysis (TEA) as well as environmental and social life cycle assessment (LCA; S-LCA) and evaluate its business models accordingly. Early and ongoing involvement of various stakeholders will enable the development of processes and products that closely match market needs.

Funded

The project is supported by the Circular Bio-based Europe Joint Undertaking and its members. Funded by the European Union. GA ID 101214432. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CBE JU. Neither the European Union nor the CBE JU can be held responsible for them.